BIONIC-FINISH® ECO

RACL offers tailor-made solutions not only for everyday clothing but also for high-end textile effects required for technical and automotive textiles. It ensures that these synergistic RUDOLF GROUP® technologies are easily available to all users in India.

The Company ensures that the substances and materials having carcinogenic, teratogenic or environmentally harmful properties are avoided while manufacturing these products.

BIONIC-FINISH® ECO

Impregnation for ecologists

Why do feathers of birds do not become wet? How does this type of water repellency in nature work without per-fluorinated compounds?

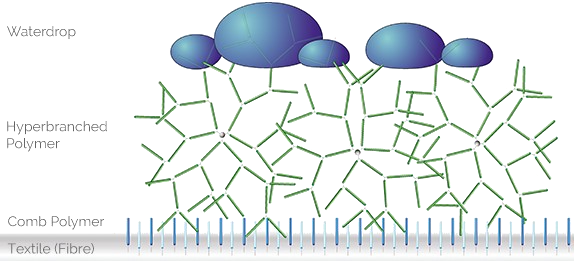

Hydrophobic finishing with BIONIC-FINISH® ECO is based on a fluorine-free recipe. This concept is based on hyper-branched, hydrophobic polymers with ramified structures like in tree tops, oriented in an orderly manner on textiles and crystallise on specifically adjusted comb polymers. Addition of boosters (crosslinking agents) ensure optimum attachment and durability on many fibre substrates. This gives durable water repellent effect.

Hyper-branched polymers can be produced step by step by combining multifunctional components. With each synthetic step of these hyper-branched polymers, the number of reactive end groups grow exponentially.

For optimum orientation and attaching to the fibre surface, RUCO-DRY® ECO and RUCO-DRY® ECO PLUS are the finishing products of BIONIC-FINISH® ECO for optimum orientation and attaching to the fibre surface,. The water-repellent effect obtained by initial textile finishing has so far only been possible with fluorocarbon polymers.

Bionic is the future!

The Company develops novel, sustainable and ecologically advantageous technologies in the field of hydrophobic finishing. BIONIC-FINISH® ECO is a step forward for ecological solutions in hydrophobic finishing of textiles.

- imparts PFC free finishing

- provides formaldehyde-free effects

- achieves water-repellent

- offers good softness compared to conventional finishes

- improves sewability during stitching

- provides high wear comfort of sports and outdoor jackets with membrane technology

- maintains breathability of textile

- resistant to abrasion and wear

- effective when tumble drying after home laundry

- cost-effective alternative to fluorocarbon resin finishing

Per-fluorinated compounds are not used for manufacturing BIONIC-FINISH® ECO products. This finish avoids release of PFOS and PFOA and presents new perspectives

to the clothing sector.

BIONIC-FINISH® ECO offers security to the manufacturers for protecting their labels and textiles.

Applications:

- uniform clothing

- outdoor jackets

- trousers

- technical yarns

- tent fabrics